Let's build railroads for the future

Sustainable polymer railway sleepers

Our solutions:

Sustainable polymer railway sleepers

Our solutions:

The increasing scarcity of hardwood, deforestation, and the ban on creosote, together with spiralling track maintenance costs, were the main drivers for Lankhorst to develop the KLP® Hybrid Polymer Sleeper. Providing ease of installation, machinability and a product weight comparable to wood, the KLP® Hybrid Polymer Sleeper seamlessly integrates into existing railway infrastructure. Moreover, thanks to its adaptable design, the KLP® sleeper provides the ideal solution when dimensional restrictions come into play.

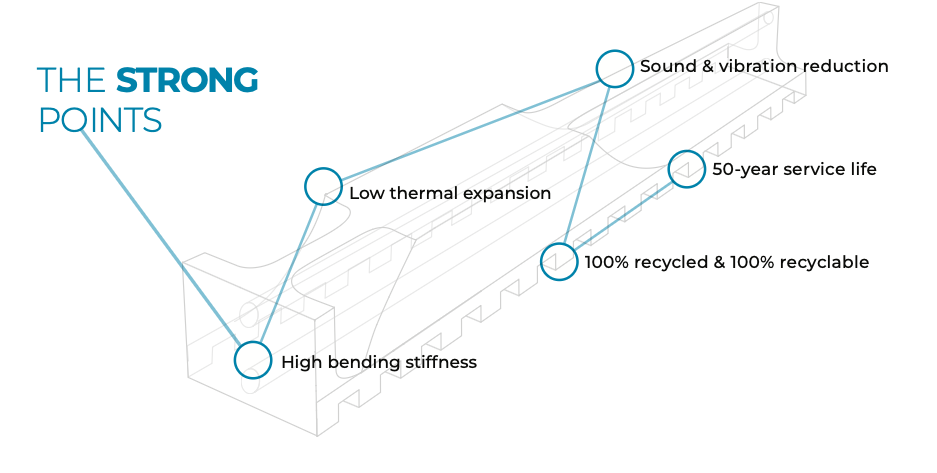

KLP® sleepers offer a 50+ year service life versus oak sleepers' 8-12 years. One installation replaces 4-6 wooden cycles, dramatically cutting lifecycle costs and downtime. Unlike wood, they are impervious to rot, splitting or degradation from moisture, fungus or insects.

Compared to concrete, KLP® sleepers provide superior lateral resistance through the innovative hedgehog design and optimal track stiffness without concrete's rigidity problems or cracking from dynamic loads. The result: predictable performance with substantially lower Total Cost of Ownership.

Every KLP® sleeper begins as 100% recycled plastic waste, where we transform discarded materials into high-performance railway infrastructure. By 2024, our production has upcycled over 10 million kilograms of plastic waste, preventing it from incineration or landfill.

After 50+ years of service, the cycle continues. KLP® sleepers can be reground with steel inserts removed and reused, creating material for the next generation of sleepers or other KLP® products. This creates a truly circular economy, from waste to infrastructure and back to new products again.

The maintenance-free KLP® Hybrid Polymer Sleeper is manufactured from high quality, ductile polymer with encased steel bars. This provides high strength properties, low thermal expansion and excellent damping characteristics. The steel reinforcement is strategically placed for maximum effectiveness without interfering with fastening systems. This delivers the longitudinal and lateral stiffness needed to maintain track gauge under all conditions while making it suitable for strength and impact critical situations. The recycled polymer simultaneously serves as an efficient impact absorber and sound damper, reducing noise levels and enhancing rail infrastructure longevity.

Request our Technical Director's research paper analyzing how recycled plastic sleeper parameters influence track stiffness and performance. Essential engineering insights for railway infrastructure professionals.

For the first time in nearly two centuries, track owners have the flexibility to precisely adjust their choice of railway sleepers and address operational and environmental challenges. The KLP® Hybrid Polymer Sleeper range is defined by its optimized designs, specifically developed for a diverse range of applications, including tracks, turnouts, bridges and tunnels. The KLP® Hybrid Polymer Sleepers have been subjected to the design approval tests as described in the ISO 12856-2:2020 standard for polymeric composite sleepers, bearers and transoms.

Our engineers are always ready to discuss your project requirements!

Many of our products are evaluated and approved by TÜV Germany and Lankhorst Engineered Products is ISO 9001, ISO 14001 and ISO 45001 certified.